Optical Clear Adhesives (OCAs) commonly used in electronic devices including smartphones and tablets are adhesives for display panels such as touch panels. These adhesives are applied to various materials such as glass, acrylic, polycarbonate, and films. With a direct impact on display performance, OCAs are required to retain consistent optical uniformity, as well as being resistant to delamination or air bubble generation. A high-quality lamination that satisfies such requirements is indispensable for improving product manufacturing quality.

Here is a case of a device manufacturer requesting a solution from us.

Requests from the customer

- They had an adhesive layer problem with a display panel. Gouging at the square display corner, causing air bubbles and delamination, and they asked us to improve it.

Solution using our cutting mold

- Erased polishing marks from the edge of the Thomson blade, and gave it a mirror-finish.

- Re-profiled the blade with an acute bevel angle, using our original section design.

- Applied coating to enable smooth release of the remaining material from the mold.

- Improved the sponge characteristics during punching.

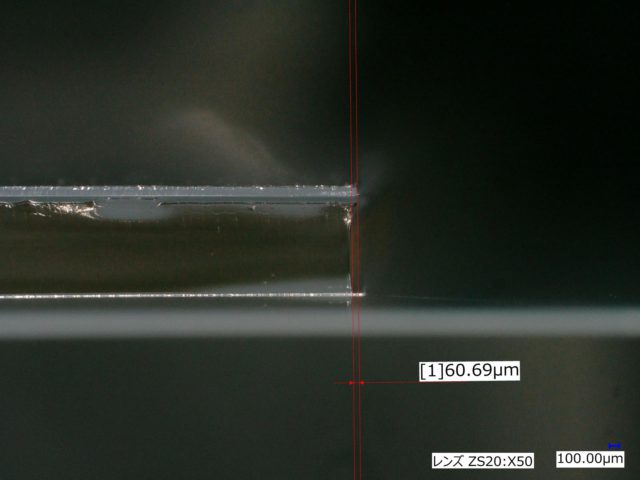

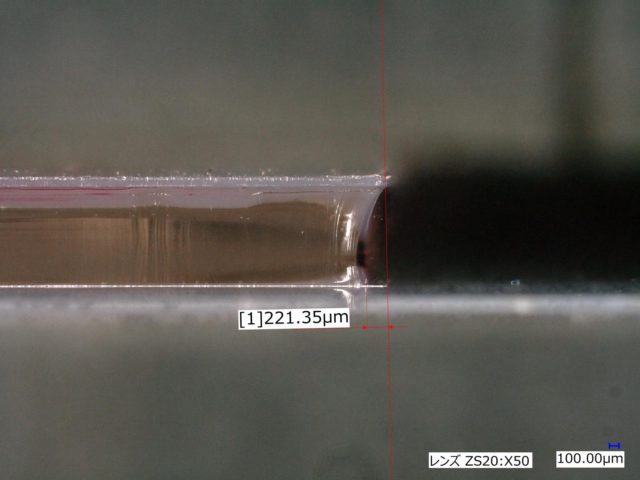

Within the cross section of the soft OCA adhesive layer between the upper and lower PET films, the conventional cutting mold (by a competitor) has significant gouging. While the Nagoya Hagata mold has an almost vertical, clean sectional line, giving a significant improvement in the film laminate quality. This quality mold has realized great improvements, with reduced delamination and air bubbles that were annoying the customer.